The BurcHowdy Shaft is making progress. There’s likely 10 to 15 test shafts in each of those black birch logs. The corner wheel folded when I rolled the entire tree on a cart into the garage.

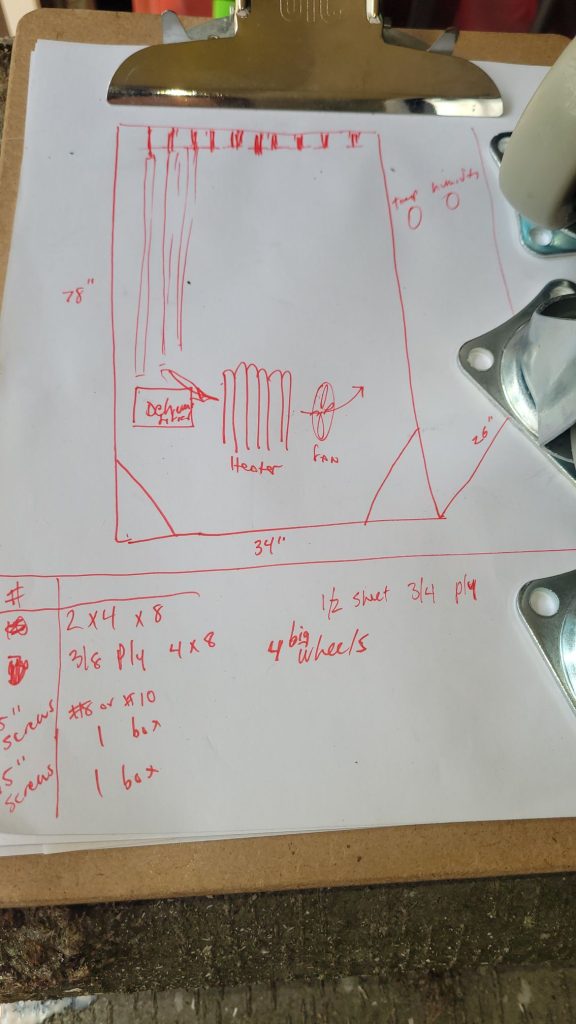

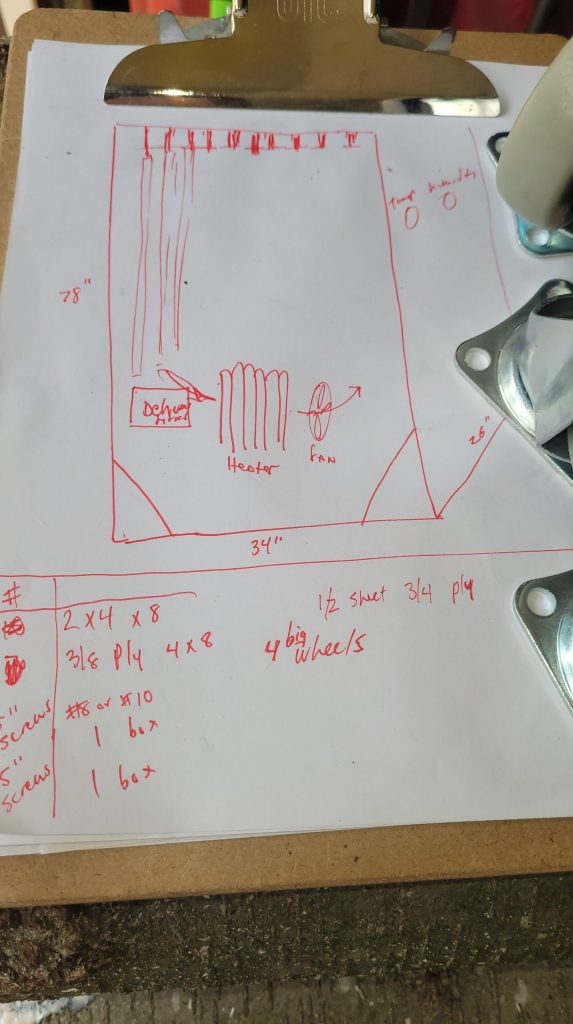

But before I can saw them I want a new slow heater/kiln to put them in, one designed for the purpose. It’ll have a heater, dehumidifier and fan, temp and humidity guages inside and the numbers will be automatically tracked. The shafts will hang vertically with plenty of room for air circulation.

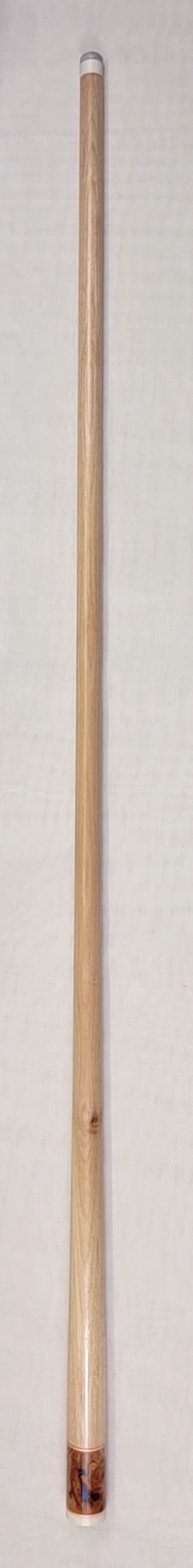

When they reach a low enough humidity to torrefy, a number I will determine by testing, shafts will then be torrefied, or baked til their sugar’s hard, (that’s a name for a cue, for sure) which will make them lighter, stiffer, and less prone to deflection.

Kielwood is hard maple. Black birch has better dynamics across the board and will be both lighter and stronger when torrefied than maple.

I’m using overtime hours for the project, evenings and weekends, so I can keep up with the stick biz.

Better get your Black BurcHowdy now. There’s only 28 left and once they sell out, the price goes up and they go on back order until production can catch up.

I can’t wait for you all to see the vision unfold. God gave me a mental download that lasted two seconds and unfolded the whole thing like gears levers and pulleys. I can see it all from beginning to end except the plot twists that keep it exciting.

Check out the BurcHowdy tab and stick one of these bad boys on a payment plan. I aim to make the best low deflection wood shaft in the world.

Why am I preselling shafts? Because I know that at some point before they are ready enough of you will catch the vision that allows me to begin serving a giant market with a company that didn’t take on debt, has no master but God, and is free to be a model of the economics of Love Thy Neighbor.

I got ahold of something, people. Be sure to stay tuned.